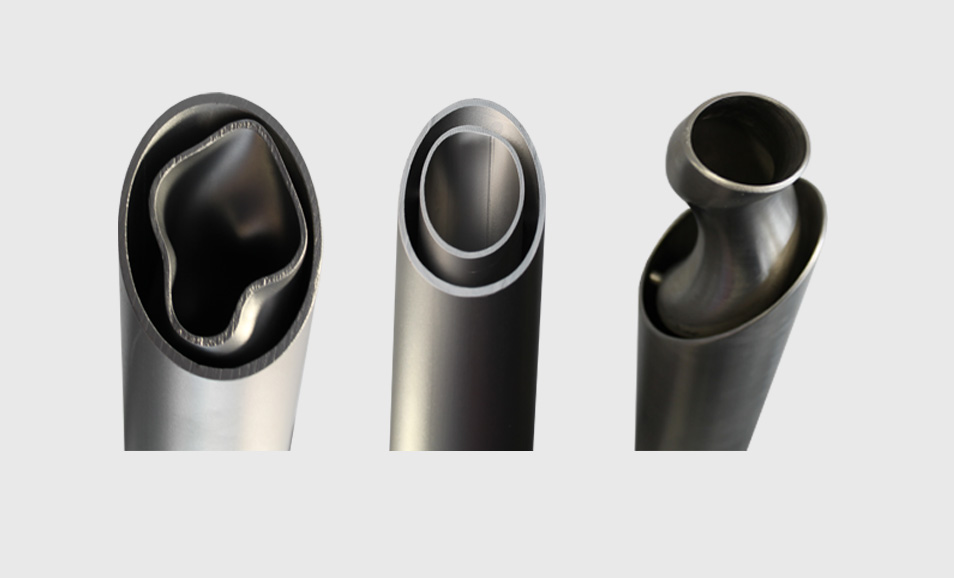

High pressure heat exchanger – Type HD WT

Capacity from 0,5 up to 20 m3/h. Pressure up to 240 bar.

Utilisation

The tubular heat exchanger is heating and cooling fluids under high pressure and is designed for industrial, food or pharmaceutical plants.

Description

Application

MR heat exchanger – Type MR WT

Capacity from 0,5 up to 20 m3/h. Pressure up to 20 bar.

Utilisation

The tubular heat exchanger is heating and cooling fluids in countercurrent with steam or water.

Description

Application

Double pipe heat exchanger / twin pipe – Type DR WT

Capacity from 0,1 up to 20 m3/h. Pressure up to 100 bar.

Utilisation

Regenerative heat transfer direct or with water safety cycle indirect. Or heating and cooling fluids in countercurrent with steam or water.

Description

Application

Coiled pipe – Type RHH

Capacity from 0,1 up to 25 m3/h. Pressure up to 100 bar.

Utilisation

Heat holding pipes or for installation in vessels or reactors.